BUILDING

EVOLUTION

The global awareness for a world with a higher quality of life, as well as increasingly demanding global regulations, leaves no option for every party involved in a building process (specifiers, manufacturers, engineers and architects, distributors, installers, construction companies, promoters and final customers) other than to move towards a vision of quality and sustainable materials, more technical construction systems and materials which are better developed and longer lasting. Therefore, this requires a commitment to professionalism and good practices in both the present and the future, while acting in compliance with laws and procedures which are increasingly adapted to the real world.

PROCEDURE

The acoustic testing by manufacturers of materials and systems that were previously considered valid for completing a building are not permitted by current legislation. The reason for this is that acoustic testing in external laboratories only considers the direct route to which the test materials or systems are subjected. The building site is where the direct data is obtained, but also the indirect data from all possible sources of noise: impacts, embedded pipes and structural transmissions, among other factors.

ACTION

This is where acoustic engineering and specialist acoustic technicians come into their own and inevitably grow in importance. By using the appropriate calculation tools and working closely with manufacturers such as AIT, they guarantee acoustic results in accordance with current regulations, whether in new buildings, in commencing new operations or when carrying out professional renovation work.

In these circumstances, a manufacturer cannot act on its own and guarantee standards in a building project. Venturing into this area could have consequences for the builder and responsible parties and lead to completely unnecessary post-building procedures.

OUR MATERIALS

The acoustic materials developed and manufactured by AIT have been tested in official and independent external laboratories for their performance, which is essential data for the calculation of solutions by specialists, if required by regulations. Furthermore, the added value of AIT resides in the fact that the materials are subjected to exhaustive quality controls due to their direct link to the automotive industry. Our heavy synthetic sheet is 100% free of asphalt derivatives and is characterized by:

- Odour emission control

- Oil migration control

- No shrinking

- No hardening in the cold

- No softening in the heat

- High mechanical tensile strength

- Long lasting

- Heavy sheet from recycling and 100% recyclable

The proof of all this is the absence of any kind of surface protection, because it needs neither film nor fabric. The absence of such an additive in the product does not alter the acoustic behaviour of its formulation, such as elongation at break and other factors, which avoids the destabilisation of its properties caused by the additive.

The right choice of system and the inclusion of these materials in the initial phase of the project avoid potential sound problems in a new building or renovation, where once the work has been completed, rectification would involve unanticipated costly investment that very often would no longer be affordable.

Investment in product quality and projects that are carried out properly always pays off in the long term and, in that regard, you can always count on us.

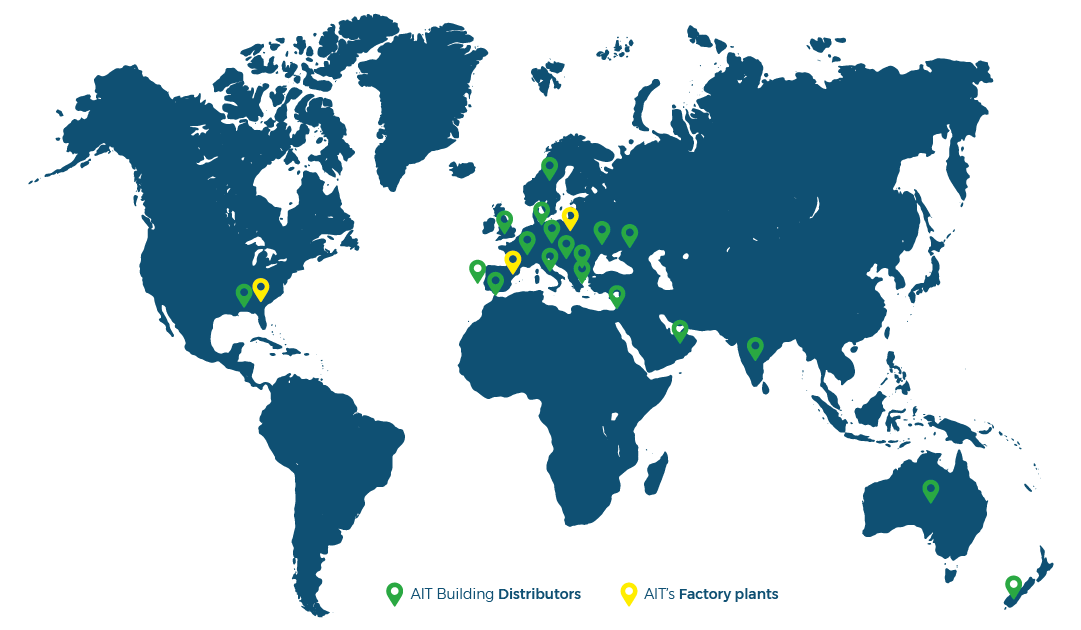

AIT materials are only available from specialist soundproofing centres.

DISTRIBUTORS